I also believe, that the RAACO compatible 3D inserts can yet be optimized.

HEARKEN ALL 3D-INSERT DESIGNERS!

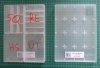

This is the current most widespread 3D RAACO-compatible design:

Basically, this design is fine:

Basically, this design is fine:

- It can be printed to be stackable in 2 or 3 layers.

- It is friendly to tweezer retrieval

- It allows for "optical" identification of counter (my favorite) making labels unneccessary

- It allows maximum flexibility within an Assorter by allowing any combination of 1/2" and 5/8" counter variants or 2 or 3 layer stacks of inserts.

- It is easy to retrieve an insert for counters needed to be placed at the side of the playing area requiring minimum table space (see previous post).

But this is its current issue that can be improved:

- These inserts would shift laterally if stacked unless they are fixed in place by neighboring inserts.

This is, how the design can be improved to allow stacking without shifting:

In the picture above, please note the locations of the inserts, which I have marked with small red cricles.

Mainly these but also possibly other locations could be used to implement notches or indentations (at the bottom of the insert) and protrusions (on the top of the insert). The protrusions on top of the insert would fit into the notches of the next insert stacked on top of it, thus preventing lateral shifting.

For technical reasons of 3D printing, the notches need to be at the bottom of the insert, while the protrusions need to be on the top of it.

Probably, you already understand what I mean. I will add a drawing (excuse the low quality) to illustrate:

Protusions could be placed at the corners of an insert with matching notches in the baseplate of it.

Alternatively, a pattern of protusions could be placed in the middle of the tops of the "crosses" of the inserts and a matching pattern of notches in its baseplate.

What say you?

von Marwitz